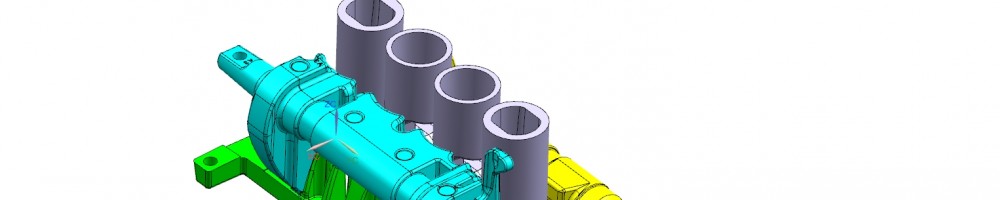

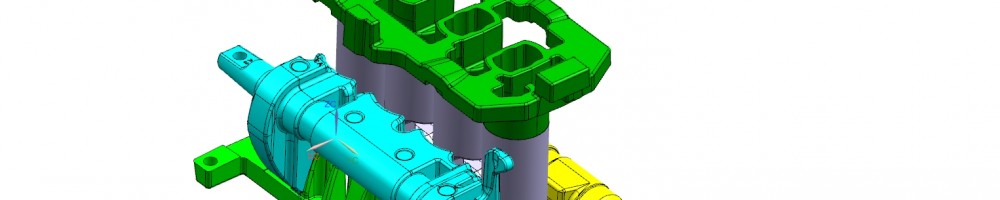

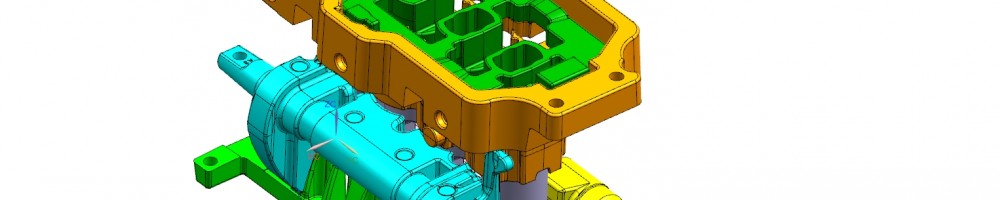

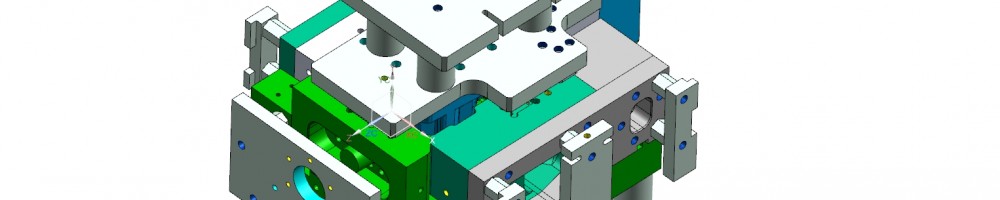

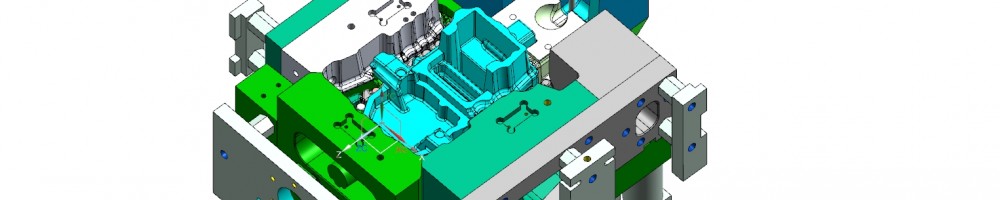

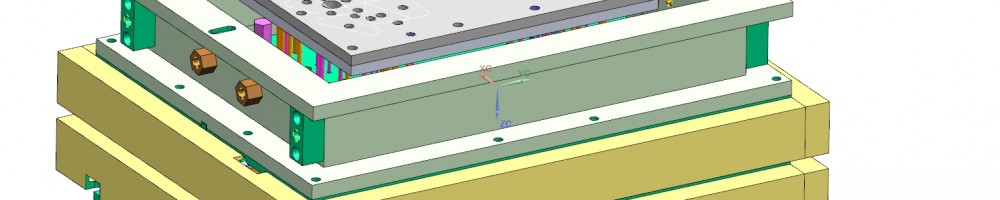

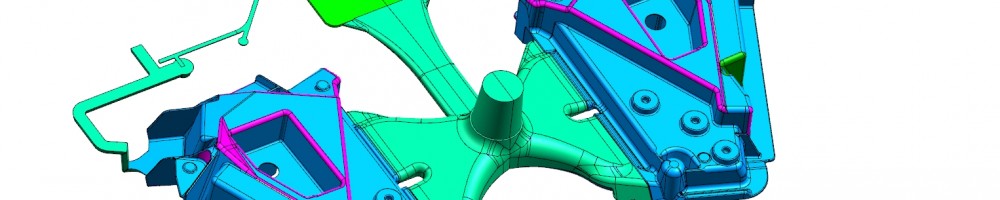

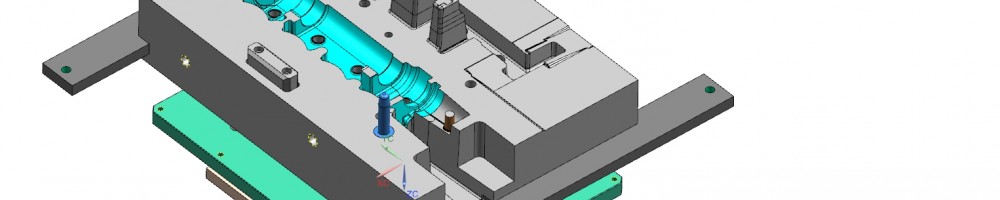

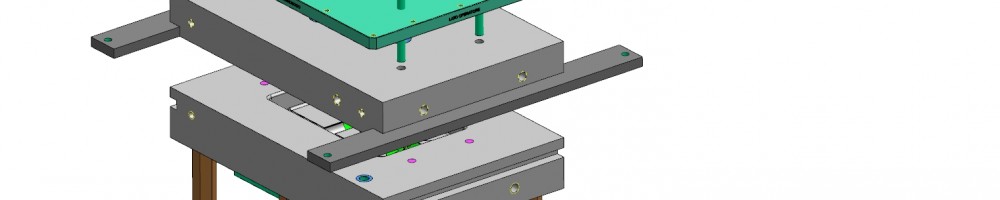

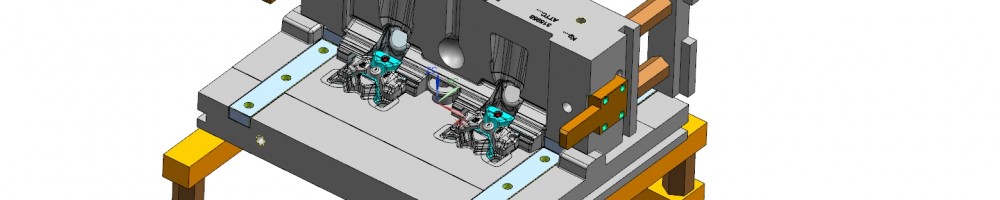

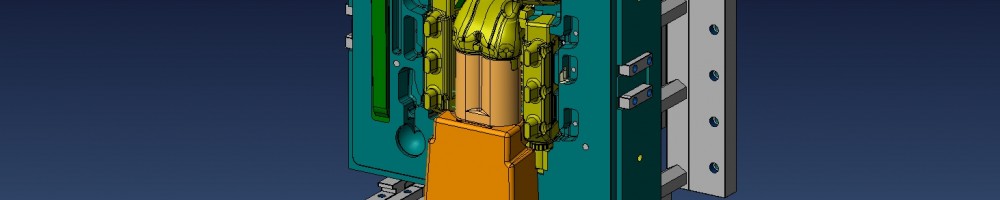

The project design phase is carried out together with the customer, assessing, case by case, the problems we, but above all, the customer, may encounter during production with low pressure moulds, gravity moulds, core boxes or shell molding, cordis, cleantech cores.

The department is equipped with three work stations guaranteeing a capacity of 3,500 hours/year.

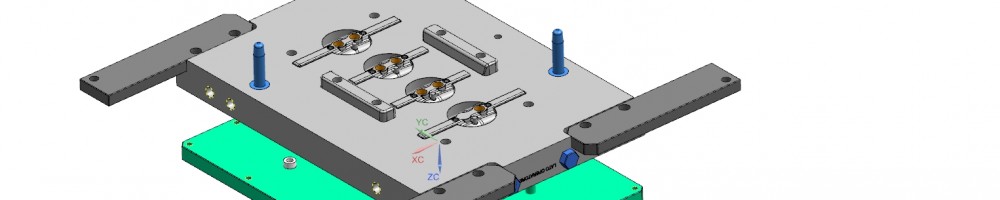

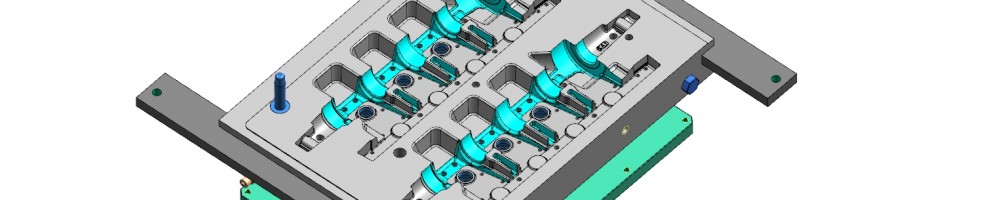

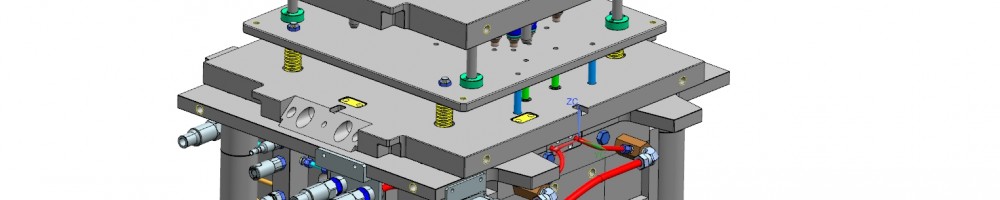

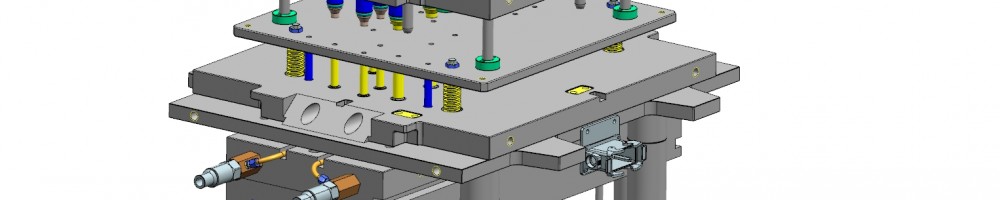

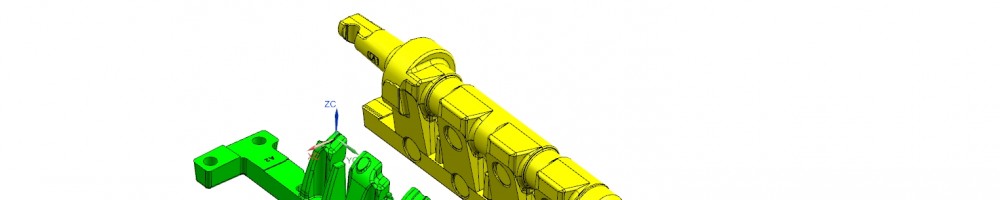

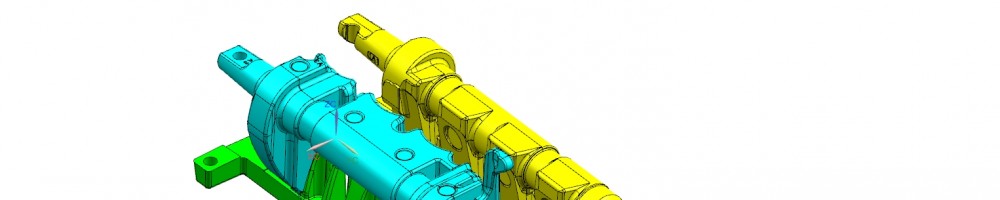

The devices are designed using CAD 2D and 3D devices, able to import and export any of the current formats used by other systems: DWG, DXF, IGES, STL, STEP, Parasolid, Catia, ProEngineer, SolidWorks, Unigraphics and many others.

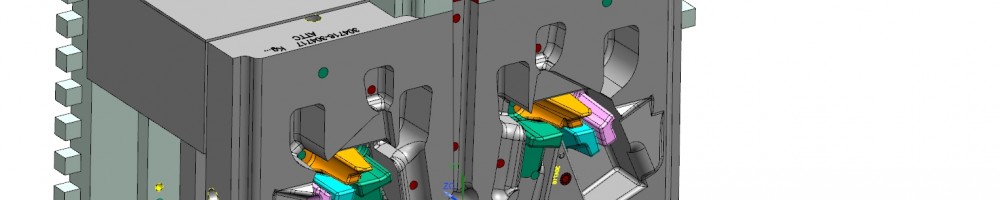

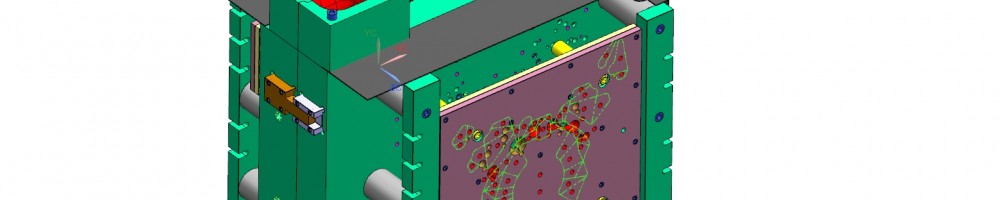

Once the project design phase is finished and solid models have been created on CAD 3D, we go on to use CAM to define the roughing, semi-finishing and finishing tool paths, which will then be sent to the CNC machines for actual production.

The project design department then follows the first sampling of the tools, to check that they function and comply with the customer’s specifications.