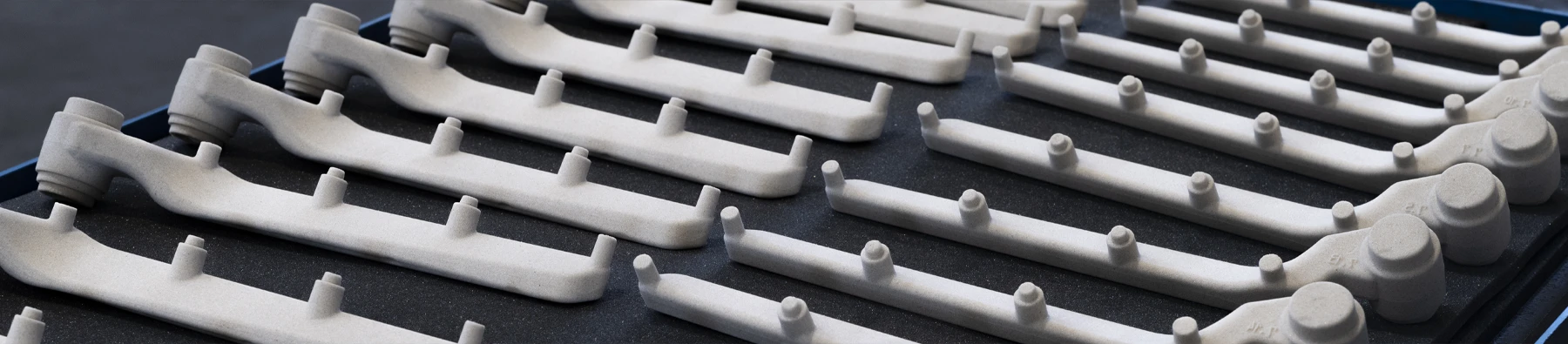

Cold-box core production

Production of high-performance cores

Production of high-performance cores

In addition to inorganic process production, at zetakern we also specialise in the manufacture of foundry cores using the cold-box process. Our constant search for solutions in line with the needs of modern foundries has led us to select and maximise the performance of these two processes.

Our decades of experience in core moulding allow us to master the delicate balance of sand and binder mixtures, producing cores that lead to castings with extremely high quality standards. The Cold-Box production system is carried out "cold": the core boxes are not heated, with the significant advantage that they can therefore also be made from non-metallic materials, resulting in considerable cost savings.

Our decades of experience in core moulding allow us to master the delicate balance of sand and binder mixtures, producing cores that lead to castings with extremely high quality standards. The Cold-Box production system is carried out "cold": the core boxes are not heated, with the significant advantage that they can therefore also be made from non-metallic materials, resulting in considerable cost savings.

The key advantages of the Cold-Box process

In this production system, the sand is also mixed with binding components but, unlike the Inorganic Process, the hardening of the mixture is activated by nebulising a catalyst component, allowing cold moulding with several benefits:

- lower overall costs

- flexibility in terms of tooling materials: wood, resin, metal

- faster cycle times

- optimal shake-out properties

- excellent storage life of the cores

This process is particularly suitable for the moulding of very complex shapes, offering great dimensional flexibility.

Rigorous inspection tests

Rigorous inspection tests

At the end of the production process, the cores obtained are subjected to thorough sample tests carried out by our Quality Control department, in order to verify full compliance with the required specifications. After this stage, if requested, any additional machining or assembly operations can be performed on the cores.

Meticulous packaging

Meticulous packaging

Packaging is also a critical activity in our sector: the cores must be packed with great care – we could almost call it "customised" – according to their size and shape, so as to ensure the perfect integrity of the pieces during storage in our warehouses and throughout transport to their final destination.