Foundry core production

A history that began in the 1970s

A history that began in the 1970s

The current company was founded in 2014, but its roots go back to 1976, when Agostino Zanini created Modelleria Zanini Snc, initially operating in the production of wooden patterns for sand foundries and, later on, also in the production of metal moulds for light-alloy foundries.

In the following years, responding to requests from some customers to also supply sample core boxes, the company equipped itself with several machines for the production of cores using the "croning" process.

In the following years, responding to requests from some customers to also supply sample core boxes, the company equipped itself with several machines for the production of cores using the "croning" process.

Core production started In 1999

Core production started In 1999

Given the positive market response and growing demand, what had started as a small artisan business expanded to the point of requiring a dedicated production area and a specific reference in the company name. This led, in 1999, to the creation of Modelleria ed Animisteria Franciacorta Srl, specialised in producing cores for ventilated brake discs.

Later, following market trends, the company decided to change direction by reorganising its production, targeting the light-alloy market and beyond, and adopting the name "Zetakern".

Later, following market trends, the company decided to change direction by reorganising its production, targeting the light-alloy market and beyond, and adopting the name "Zetakern".

Today, a benchmark in the industrial sector

Today, a benchmark in the industrial sector

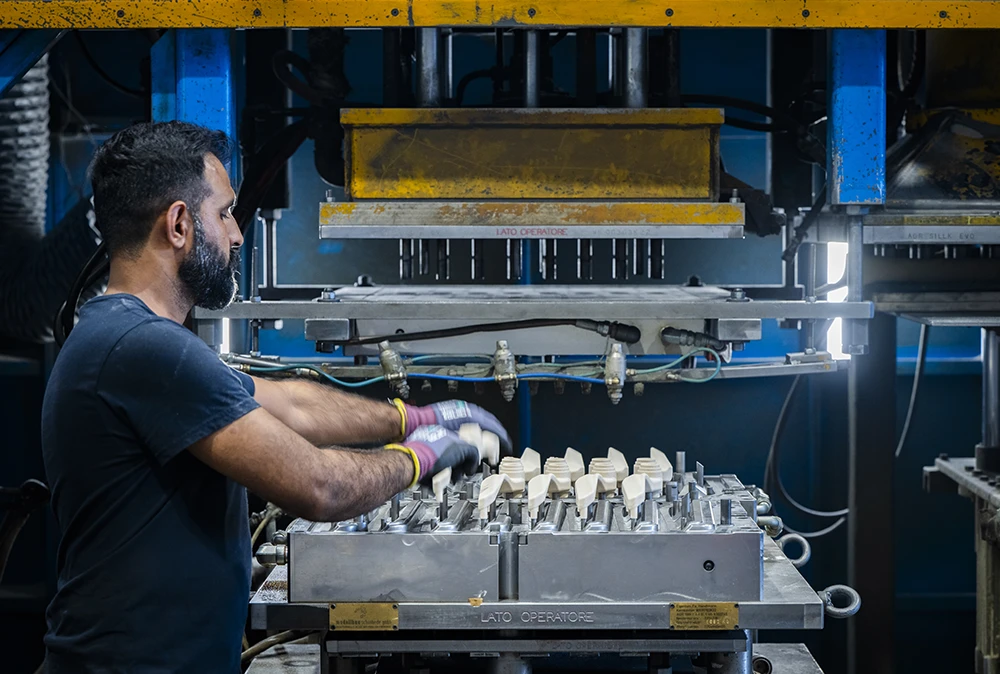

Today, the company is a point of reference in the field of core production for foundries, offering long-standing experience and expertise that is developed and refined every day "in the field".

Over the years, we have used various methods for core manufacturing, always striving to keep pace with new technologies: in 2010 we were the first in Italy to install a machine for the inorganic process. We eventually decided to focus on the two most high-performing systems: the Inorganic Process and the Cold-Box Process, which we present in detail on this website.

Over the years, we have used various methods for core manufacturing, always striving to keep pace with new technologies: in 2010 we were the first in Italy to install a machine for the inorganic process. We eventually decided to focus on the two most high-performing systems: the Inorganic Process and the Cold-Box Process, which we present in detail on this website.

Know-how that makes the difference

Know-how that makes the difference

Our decades of experience in core moulding allow us to master the delicate balance of formulations, obtaining cores that lead to castings with the highest quality standards.

In addition, our in-depth process knowledge, combined with past experience in mould manufacturing, enables Zetakern to offer customers solutions tailored to their specific needs, supporting them right from the initial design stage.

In addition, our in-depth process knowledge, combined with past experience in mould manufacturing, enables Zetakern to offer customers solutions tailored to their specific needs, supporting them right from the initial design stage.

A machine fleet for every type of order

A machine fleet for every type of order

In our spacious production departments, we have three machines dedicated to the Inorganic Process: two 40-litre machines and one 20-litre machine, for a total production capacity of 400 tons per month on two shifts.

As for the Cold-Box Process, we have a machine capable of producing cores from 0,1 Kg to 35 Kg, with a production capacity of 100 tons per month. These figures allow us to guarantee perfectly manufactured products for small, medium and large orders, with consistently on-time deliveries.

As for the Cold-Box Process, we have a machine capable of producing cores from 0,1 Kg to 35 Kg, with a production capacity of 100 tons per month. These figures allow us to guarantee perfectly manufactured products for small, medium and large orders, with consistently on-time deliveries.