Quality

Zetakern is a certified company

Zetakern is a certified company

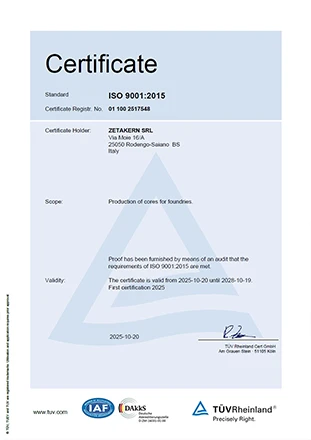

Our continuous commitment to optimising production cycles and ensuring perfectly manufactured products has found its natural recognition in the achievement of iso 9001:2015 certification, which attests to the quality of our processing and production processes.

Control procedures for consistent quality

Control procedures for consistent quality

The ultimate goal of our work is to deliver an impeccable product to the customer. To this end, at Zetakern we have developed a series of rigorous procedures which, as confirmed by our ISO 9001 certification, enable us to produce highly reliable components with consistently high quality.

We carry out thorough inspections throughout all stages of the production cycle and perform a number of in-house laboratory tests on the finished product. In particular, we analyse hardness, bending strength, moisture content and loss on ignition – all key parameters to ensure defect-free casting.

We carry out thorough inspections throughout all stages of the production cycle and perform a number of in-house laboratory tests on the finished product. In particular, we analyse hardness, bending strength, moisture content and loss on ignition – all key parameters to ensure defect-free casting.

Hardness and bending strength

Hardness and bending strength

Monitoring these characteristics is especially important in order to achieve the perfect balance between resistance during casting and ease of shake-out at the customer's plant.

Moisture

Moisture

Monitoring this factor allows us to produce cores with excellent durability and to minimise the risk of deformation both during storage and later during casting.

Loss on ignition

Loss on ignition

The analysis of this value makes it possible to optimise casting by reducing gas emissions and, consequently, the risk of porosity defects or gas inclusions.